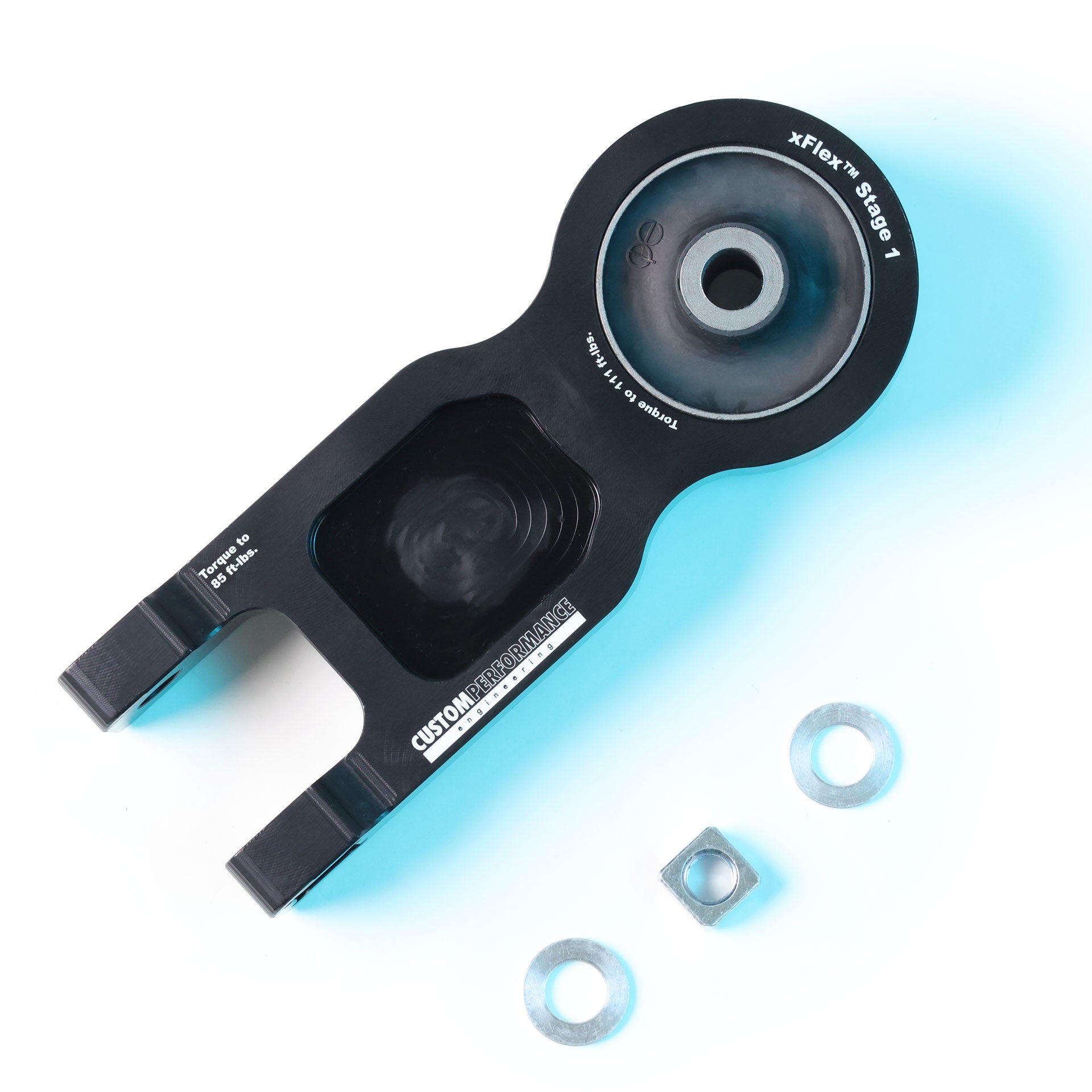

Ford 2.7 EcoBoost xFlex™ RMM

Our Rear Motor Mount is unique compared to our competitors mounts both in form and in function. We have incorporated a unique method of holding the mount in the vehicle.

2.7 EcoBoost RMM Rear Motor Mount Features

- Billet CNC construction

- EPDM Bushing

- CNC lathed aluminum bushing spacers

- Stabilize the engine rotational movement

- 75A durometer

- All necessary hardware included

Instead of placing all of the force on the center bushing pin, the load is distributed throughout the bushing with the CNC lathed aluminum spacers. This load distribution increases the effective stiffness of the bushing under engine loads allowing a lower durometer bushing to provide more stiffness. cp-e® goes a step further by using EPDM, a sort of rubber, bushing. Urethane begins to fail at temperatures as low as 200ºF and generally the bushings need a higher durometer rating to hold together. The Focus rear motor mount is a perfect example of when not to use urethane. The location of the mount allows a large amount of heat to be transferred to the bushing. EPDM holds up to this heat, and doesn't begin to break down and fail. EPDM has a higher density than urethane, so the bushing can have a lower durometer rating while keeping high reliability and support. Why is that good? Higher durometer ratings transfer vibrations through the vehicle and into the cabin, raising the NVH (noise, vibration, & harshness) value.

EDPM Bushing

Unlike nearly all other engine mount manufacturers, we use EPDM for our bushings. This provides much more vibration resistance when compared to polyurethane. This material is also extremely resilient and is able to stretch and even develop small cracks without affecting its structural integrity. EPDM is much more expensive to produce, but it is a far superior bushing material.